Microbes: Part 3, #22

Precision fermentation - producing compounds with microbes

Hello Human,

Welcome again to the world of science and climate solutions!

Today, we’ll continue one more time with the microbe deep dive series! We’ll focus on a fascinating technology called precision fermentation. In precision fermentation, microbes are used as tiny factories to manufacture valuable compounds like proteins and chemicals. Wow!

If you haven’t yet read Part 1 (Introduction to the world of microbes) or Part 2 (Microbe x climate: startups tackling climate change with microbes), I can highly recommend reading them as well.

Before we start, I have some exciting news to share!

Not a subscriber yet?

Feedback from readers

Over the past weeks, I’ve had several feedback calls with Survivaltech.club’s readers. It’s been great to get to know some of you better and hear about your ideas for Survivaltech.club’s future.

If you’d like to provide feedback and ideas, I’d love to hear them via pauliina@survivaltech.club. Alternatively, let’s book a call :)

Here are some of the amazing ideas from readers so far:

Enhance the community aspect

Add job openings

Add funding news

Add other content forms (videos etc.)

Have a steady publishing schedule

Invite guest writers

Interview researchers

Build an overview (e.g. logic tree) that shows all articles and their link to each other

We already started to bring the first two ideas into reality⬇️

Survivaltech.club’s Christmas meetup

We are happy to announce the Survivaltech.club’s Christmas meetup on Monday 20th December 9am(PT)/12pm(ET)/5pm(GMT)/6pm(CET)/7pm(EET)!

This is a relaxed online event where you can virtually walk around and get to know your fellow readers. We’ll meet at Gather Town, which provides a fun way to meet each other online. Please register to the Christmas meetup using the form below.

Looking forward to meeting you all!

Job and venture opportunities in climate tech

There are so many amazing sites that list job and venture opportunities in climate tech. So we figured out that our biggest value could be to bring these sites together.

I started crowdsourcing a list over Twitter last week. Please comment any resources that are missing on the list! I’ll publish the complete list on Survivaltech.club’s website next week.

Now let’s learn about precision fermentation!

🏭The concept - Precision fermentation

Microbes can be used as tiny factories to produce useful biomolecules for our humankind. We can instruct the microbes to produce a wide range of different kinds of substances, like proteins and fats. The instructions are given to the microbe in the language of biology, DNA.

This concept is interchangeably referred as microbial cell factories and precision fermentation. For the sake of consistency, I’ll use the term precision fermentation.

In Microbes: Part 2, we learnt about climate startups that are using microbes to produce a variety of more sustainable products like animal-free dairy-products, coffee, and chemicals. It’s important to note that not all those startups are using precision fermentation as their underlying technology. Here’s a list of those startups that are for sure using precision fermentation:

Formo to produce milk proteins

Compound Foods to produce typical molecules found in coffee

Melt & Marble to produce animal fats

C16 Biosciences to produce palmitic acid, a key ingredient of palm oil

This week I discovered that a Munich-based startup, QOA, makes chocolate via precision fermentation! QOA raised recently a $6M seed round.

📝The process overview

Let’s start with the big picture and examine how a compound can be produced with microbes. With a compound, I mean proteins, chemicals, polymers, and natural products like fragrances and flavors.

There are four steps in a (simplified) precision fermentation process:

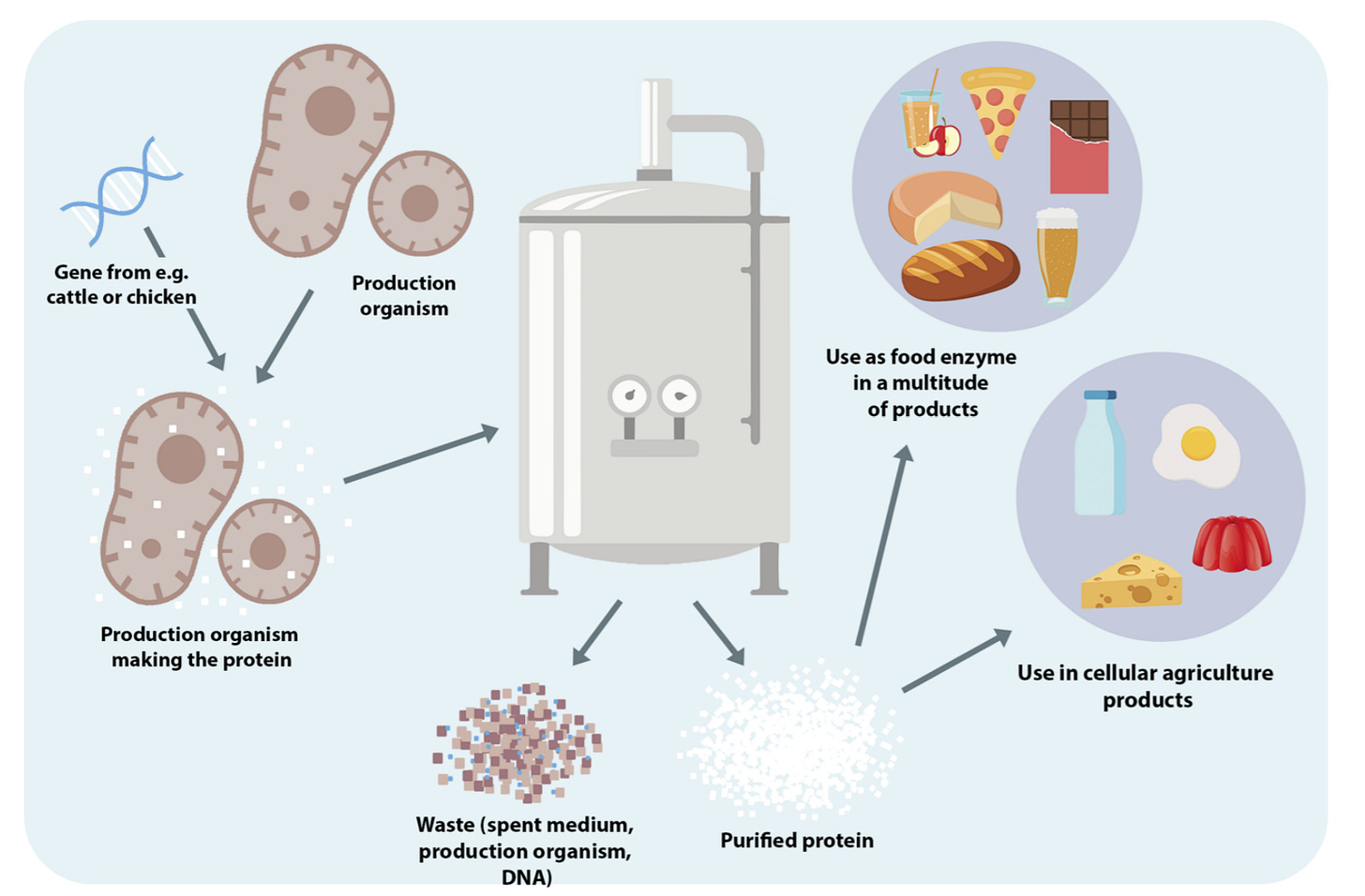

Engineer the microbe that can produce your desired compound

Grow the microbes (in a fermentor, a closed tank similar to what we use to make beer and wine)

Harvest and purify the compound from microbes

Eat or use the compound!

The photo below by The Good Food Institute illustrates the basic steps of producing animal protein via precision fermentation. As you can see, engineering a microbe involves genetic engineering. We give the production instructions to the microbe (here production organism) in the form of a gene. The gene is typically from an organism that naturally produces the desired compound (here animal protein).

This all sounds like magic! But how exactly actually does the science work? In the next sections, I’ll go through the four steps of precision fermentation.

🧬1. Engineer the microbe (Strain development)

The first step is to engineer the microbe to produce the compound that we want. We can achieve this is by modifying the microbe’s metabolism. The scientist call this step as strain development.

Before we dive into modifying the microbe’s metabolism, let’s first understand what metabolism is.

Metabolism

Metabolism is a network of chemical reactions that keep organisms like microbes and humans alive.

The three main purposes of metabolism are to:

convert food/fuel to energy to run cellular processes

convert food/fuel to building blocks for proteins, lipids, nucleic acids, and some carbohydrates

eliminate metabolic wastes

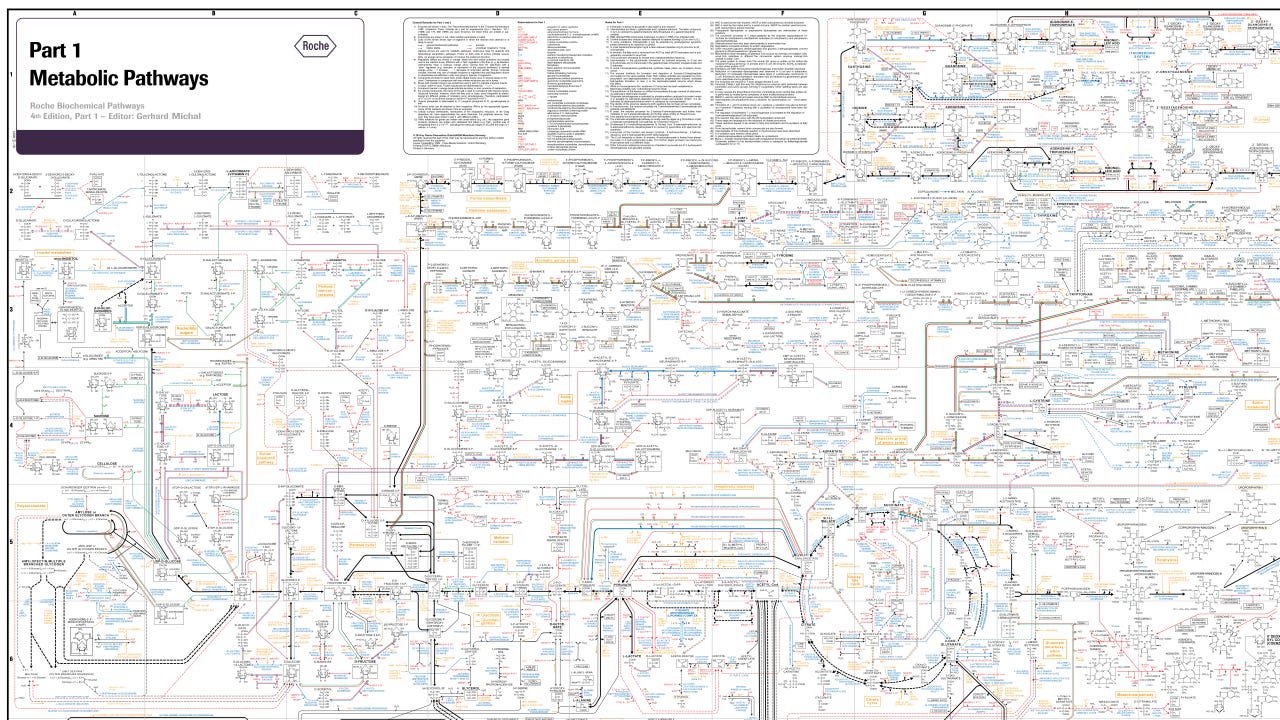

All these purposes are achieved through a number of metabolic pathways. To understand how a metabolic pathway looks like, let’s check out the energy metabolic pathway of a yeast cell.

The yeast cell (like we humans) requires energy to function. Yeast gets its energy from glucose. When yeast then breaks down glucose, it releases energy to its cellular functions. (If you want to learn more about the cellular energy called Adenosine Triphosphate (ATP), watch this Youtube video.)

Yeast’s special talent is that extract energy from food also in the absence of oxygen! As a result, ethanol and carbon dioxide get produced as by-products. This is the exact metabolic pathway that we humans have harnessed for years to make bread and beer.

In reality, the metabolic pathways are more complex. A metabolic pathway is a series of chemical reactions that all take place in a careful order. The below graphic shows the same energy metabolic pathway of a yeast cell, but in more detail.

Notice how glucose gets transformed into a number of other molecules before it ends up as ethanol and CO2. Also, notice how all the steps from one substrate into another are catalyzed by specific enzymes (e.g. Glk1, Pgi1, Pfk 1/2). (I need to do a separate deep dive on enzymes!).

This energy metabolic pathway is just one metabolic pathway of the 1500 pathways that a yeast cell has. So expect complexity when engineering these pathways…

Now that we are more familiar with metabolism and metabolic pathways, let’s see turn to metabolic engineering.

Metabolic engineering

Metabolic engineering allows us to tweak the metabolic pathways of microbes so that they will produce the compounds that we find useful (e.g. casein protein for animal-free dairy products, or palmitic acid for palm oil).

I let Prof. Jens Nielsen from Chalmers University explain how metabolic engineering is done for a yeast cell. Watch especially the part 3:25-8:30.

(Btw I love the both iBiology Techniques and iBiology Youtube channels!)

Engineering the microbe is inarguably the biggest challenge in precision fermentation. As Jens explained in the video, it takes usually numerous iterations to engineer a microbe that produces enough of the compound that we want.

If you want to have a real deep dive into this topic of strain development, I can highly recommend reading this open-source scientific article. It’s a heavy, but fascinating read!

📈2. Grow the microbes (Fermentation)

The second step is to grow the microbes via a process called fermentation.

Microbes are like humans; they need adequate food (nutrients) and suitable environment (temperature, pH etc.) to grow and flourish! These parameters are way easier to control in a closed setting. That’s why microbes are grown in a fermentor, a large closed tank.

I found this great video series about fermentation on Youtube. Watch especially the part 2:23-6:12.

👩🌾3. Harvest and purify the product

The third step is about harvesting and purifying the compound.

In precision fermentation, we don’t want the whole microbe, but rather the compound that its engineered metabolism has produced. The following video (0:30-4:08) explains well how the product is harvested from the microbes.

Next, it is time to clean the product from any other substances that may be attached to it. This is explained on the video at 1:20-5:26.

😋4. Eat or use the product!

Finally, this microbial production process is done!

Huge thanks to my amazing friend Minea Saikkala, molecular bioscientist for reviewing this article!!

Further learning

I know there’s been a lot to learn already in this article. However, those who fell in love with the concept of precision fermentation, can find further resources below:

Tools and strategies of systems metabolic engineering for the development of microbial cell factories for chemical production by Ko et. al, 2020. This is an excellent (and open-access!) article for those who want to really understand engineering microbial cell factories. It takes time to digest all the information here, just saying😄

Cellular agriculture - report by The Good Food Institute

Knowledge Base - Technology by Perfect Day

The State of Industry Report: Fermentation (2020) by The Good Food Institute

2020 Symposium on Fermentation: Fermentation 101 by The Good Food Institute

Synthetic Biology: Engineering Microbes to Solve Global Challenges by Prof. Jay Keasling

Other amazing discoveries

OpenAccessDAO is on a mission to acquire paywalled academic journals and make their content open-access for everyone to read.

This was a wild learning curve for me about precision fermentation. I hope that this post gives you the resources to help understand this fascinating and impactful technology.

Best, Pauliina

If you liked this article, share it with your fellow human beings!💚

Not a subscriber yet?

Sources

Faria-Oliveira et al. (2015). The Role of Yeast and Lactic Acid Bacteria in the Production of Fermented Beverages in South America, Food Production and Industry, Ayman Hafiz Amer Eissa, IntechOpen. Link.

The Good Food Institute (2018). Cellular agriculture: An extension of common production methods for food. Link.

Ko et al. (2020). Tools and strategies of systems metabolic engineering for the development of microbial cell factories for chemical production. Chemical Society Reviews, 49, pp. 4615-4636. Link.

Libre Texts, Chemistry (2021). Energy Metabolism. Link.