Interview with Eleonore Eisath, Founder of Beworm #23

Tackling plastic pollution

Hello Human,

Welcome to Survivaltech.club’s newsletter #23!

Today, I am honored to share an interview with the amazing Eleonore Eisath, Founder of Beworm. Beworm is a Munich-based startup is tackling plastic pollution with the help of microbes and/or enzymes.

We’ll first learn about the plastic pollution problem and then hear about the founding story of Beworm, Beworm’s solution to plastic pollution, Eleonore’s experience so far in building a science-based climate startup, and more!

Before we’ll continue, I have a couple of updates to share:

🎄Christmas Meetup registration link fixed

Last week, there was initially problem with the link. It’s been now fixed and is ready for registrations!

🎄➡️Register here: https://forms.gle/aVCLtgD7GKbAnbgQ8

Time: Monday 20th December 9am(PT)/12pm(ET)/6pm(CET)/7pm(EET)

Place: Survivaltech.club’s Space at Gather

🎄➡️Register here: https://forms.gle/aVCLtgD7GKbAnbgQ8

🌍Climate jobs and ventures opportunities on our website

As promised, you can now find the best resources for finding jobs and venture opportunities in climate tech on Survivaltech.club’s website on Resources page!

Not a subscriber yet at Survivaltech.club? Subscribe below!⬇️

🌎Introducing Beworm

The problem that Beworm is tackling

Plastic is everywhere, and it’s threatening many ecosystems. How did we end up here?

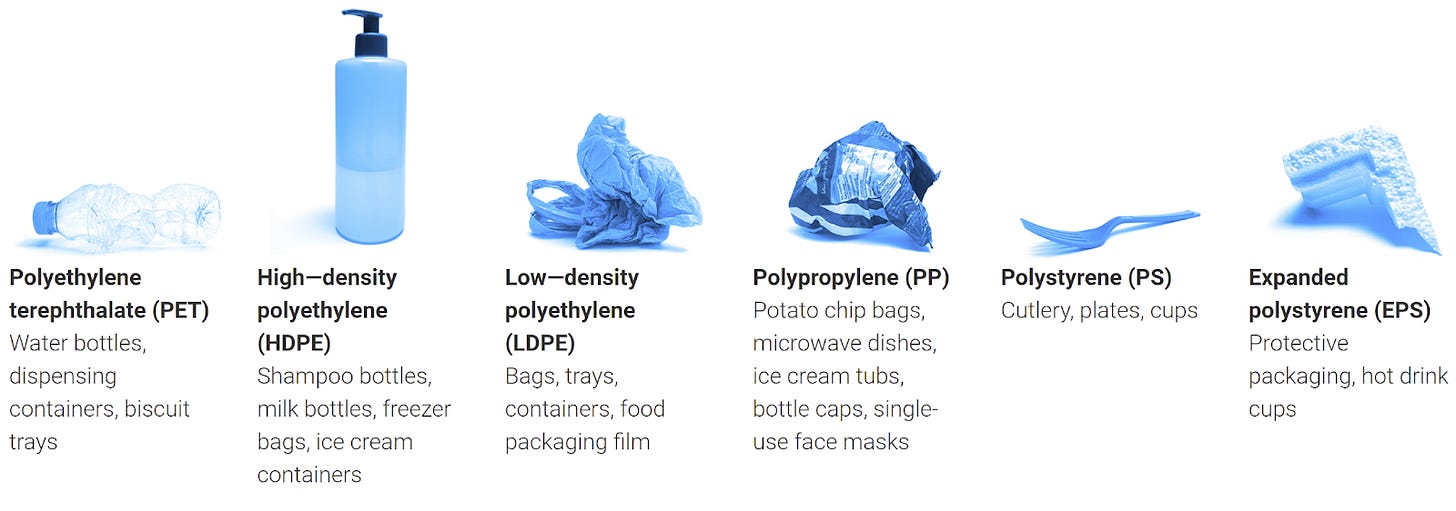

Plastic is (sadly) a true wonder material. Plastic comes in different compositions, is cheap and light-weight, and can be easily molded to various forms.

The great characteristics of plastic have led to its wide adoption across industries. Since the dawn of the plastic industry in the 1950s, over 9 billion tons of plastic has been produced until today. You would think that this is enough plastic. Still, every year our humankind produces over 400 million tons of plastic. And the trajectory is upwards.

The problem with plastic arises from how we use plastic and make it.

Firstly, our relationship with plastic use is currently linear. Only 14-18% of the plastic is recycled, 24% is incinerated, and 58-62% end up in landfills.

The below graph by Our World in Data illustrates well how most of the produced plastics (1950-2015) has ended up directly to incineration or landfill after a single-use.

Secondly, most plastic is produced from non-renewable resources, namely from crude oil and natural gas. The production and incineration of plastic caused 0.86 Gt of CO2e emissions in 2019. (For reference, our humankind emits 50 Bt / CO2e annually.)

Furthermore, producing plastic from fossil fuels means that plastic takes hundreds of years for the plastic to decompose. This is a problem on landfills but also in nature, where misplaced plastic pollution threatens biodiversity.

If you, like me, started to wonder why plastic doesn’t decompose, the reason lies in the chemical composition of plastic and microbes! Most microbes are not equipped to break down strong carbon-carbon double bonds that hold the building blocks of plastic together. Find the short explanation here, longer here. Luckily, there exists some wonder microbes who can actually decompose plastic, as you will shortly see!

Further learning about plastic

Beworm’s solutions

Beworm is a Munich-based startup aiming to increase plastic recycling.

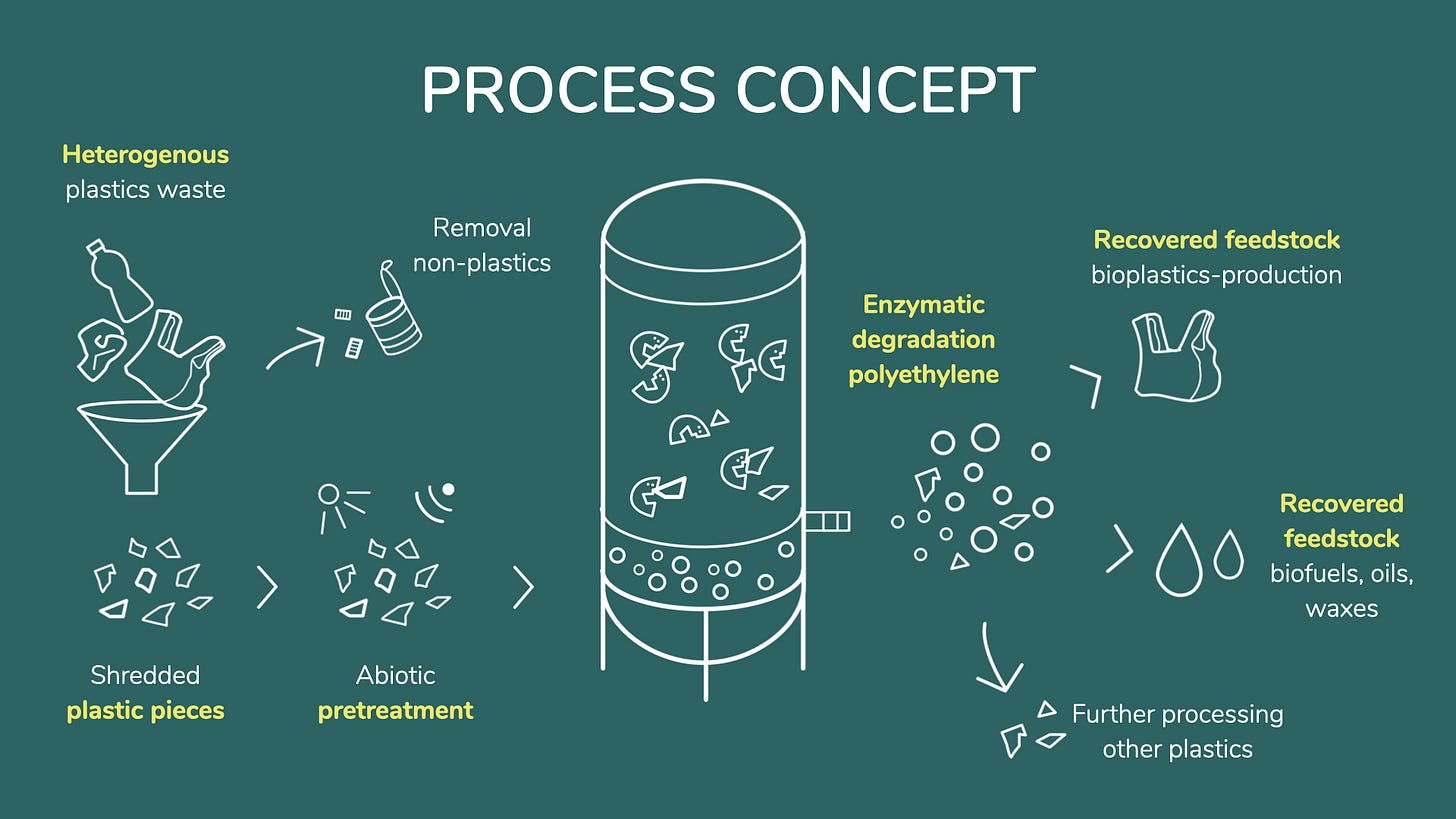

Beworm researches different microbes and their enzymes that could break down one of the most common plastics, polyethylene, into its smaller building blocks. These building blocks can then be utilized to make bioplastics, biofuels, oils, or waxes.

Beworm’s name honors the great waxworm that can survive by eating polyethylene. Waxworms served as the starting point for Beworm’s development.

🧠Wisdom from Eleonore

What’s the founding story of Beworm?

Let’s start with the fact that I’m an industrial designer by training. I studied in Venice and worked as an industrial designer for a big sports brand. After a while, I was feeling a lack of a higher sense or impact in what I did. That put me into a personal crisis.

I decided to get back to university and focus more on problem-solving. So I began my studies at the Technical University of Munich (TUM) in Germany. Right from my first semester focused on tackling plastic pollution.

I looked for concepts to tackle plastic pollution and found a newly published study on polyethylene eating waxworms. I started doing my own research and developed a first concept for an industrial use of my findings during my Master’s Thesis.

After my thesis I went to look out for biologists at my university that could build the concept in practice. I found fantastic team members, and we teamed up. The first experiments went well, and we decided to stick to the idea and continue.

When I first started to think about plastic pollution, I never thought about building a company. Instead, I just thought about how to solve plastic pollution in the best way and my contribution to it. Building a company ended up being my way of doing it..

At what stage is your development at the moment?

We are currently working on determining the most effective microbes and their enzymes to be used in our process. We have isolated microbes out of the waxworm’s gut. In addition, we also explore other microbes and their enzymes for our process.

Our process will degrade the long polyethylene chains into shorter building blocks called oligomers. The exact type of these building blocks will depend on the type of enzymes that we decide to use, and so our potential products are bioplastics, biofuels, oils, and waxes.

We are currently part of two programs, Climate Founders and Circular Futures. We are also in the process of applying for public funding and thinking about adding private funding.

What kind of business model are you planning to have?

We will most probably license our technology to companies that hold the production assets. So, we will patent our technology and then co-develop it further with partner companies to address their specific needs.

We currently look at two customer segments: 1) Waste management and 2) Chemical and petrochemical companies.

Waste management companies can implement our process to their existing waste management chains. Our Beworm process can complement the current mechanical recycling of plastic.

We are also talking to chemical and petrochemical companies. So far, we have experienced a lot of interest from this customer group. They are under a lot of pressure to change their practices, and technology can catalyze that change.

How has your experience of building a science-based climate startup been so far?

Building Beworm from the concept to what it is now has been an amazing experience. We have an awesome, diverse team with people from different backgrounds and varied interests. It’s crucial to have a team with complementing skills.

However, it’s been for sure harder than I expected it to be. The more you get into it, the more you understand how complicated things are.

Coming from an industrial design background, it has been tough even to get a foot in the door. Without a biology background, you need to watch many biology videos and read a lot, before you can even speak to anybody. Luckily, there are plenty of learning resources available, and it gets easier the more you learn!

What would your advice be to climate startup founders?

Be resilient.

Building a startup is tough. You’ll have many ups and downs, and having a resilient mindset helps you get through those.

Take care of finance.

If I could do anything differently, I would think about the finances more carefully from the very start. For example, public funding requirements are very strict, and you need to have a considerable amount of research before getting public funding.

Talk to the industry.

If you are building a product for the industry, it’s crucial to understand its real needs. The best way to find out is to talk to them from early on. Our process is desirable from society’s point of view. However, we need to make sure that the economics work for our customers.

If you liked this article, share it with your network and inspire more people to learn about science-based climate solutions and startups!💚⬇️

Not a subscriber yet at Survivaltech.club?⬇️

Best, Pauliina